Start Energy Savings Today

Acoustic Imaging

New Zealand businesses are seeing electricity cost increases of 50 – 100%. For other utilities such as CO2, prices have increased by 5 to 10-fold. While these price increases are visible, energy losses throughout manufacturing plants are not.

One of the most common areas where energy losses occur, is through compressed air and CO2 leaks. These leaks can account for as much as 20 – 50% of the system’s total consumption.

Customer Stories

Bonson Packaging

Compressed Air Systems

With compressed air being the most expensive utility for businesses, an acoustic imaging leak survey provides the best return of any energy efficiency initiative, with energy cost savings being 30+ times greater than survey costs. Frequently fixing leaks can be as simple as tightening a loose fitting.

Acoustic Imaging

Compressed Air

With compressed air being the most expensive utility for businesses, an acoustic imaging leak survey provides the best return of any energy efficiency initiative, with energy cost savings being 30+ times greater than survey costs. Frequently fixing leaks can be as simple as tightening a loose fitting.

Traditional compressible gas leak surveys, where leaks are tagged in the ‘general location’ fail to pinpoint leaks, making the identification and repair difficult. Many leaks are missed due to inaccessible locations and tags can become dislodged in production areas.

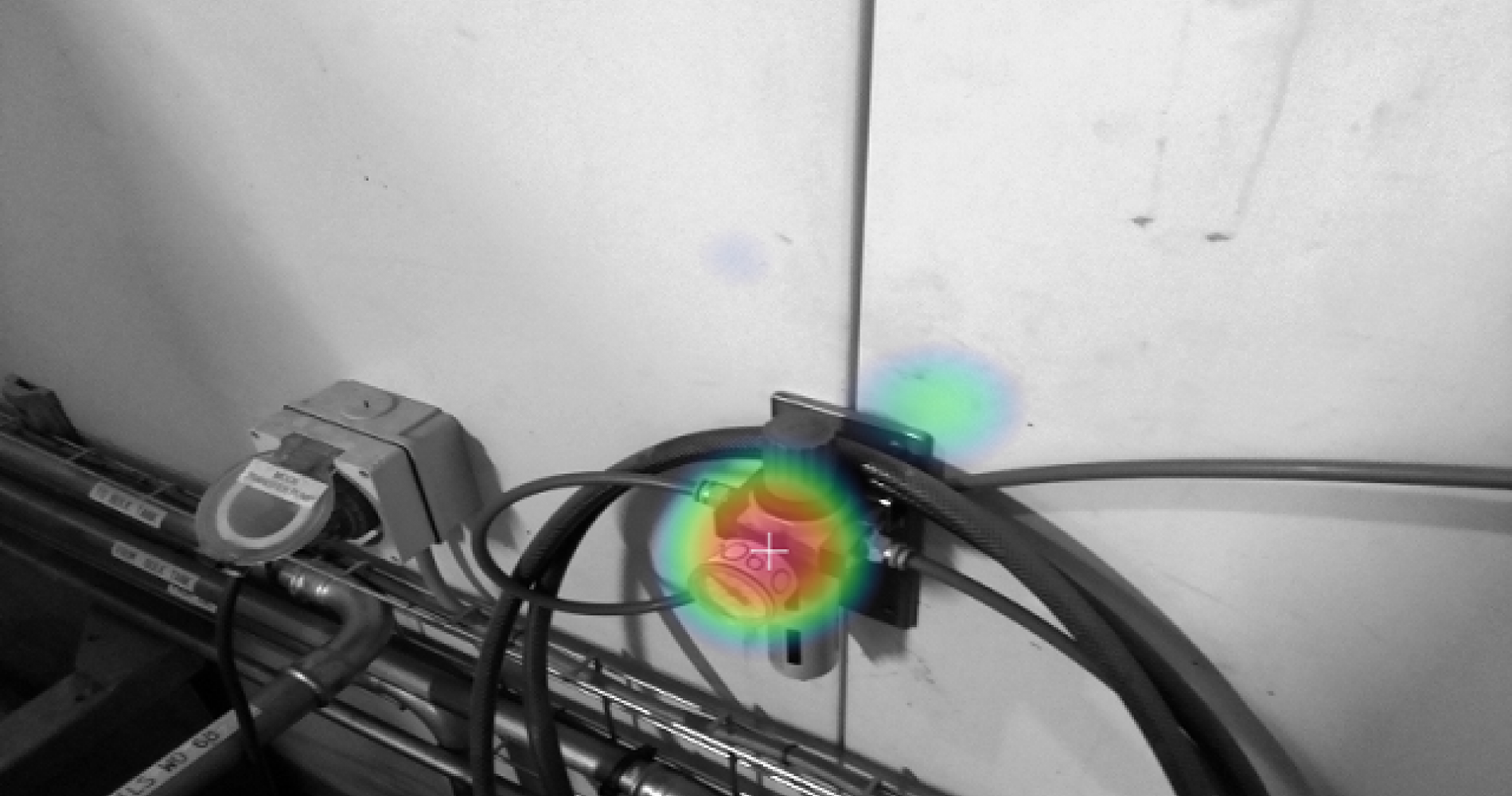

With acoustic imaging, the exact area where compressible gas leaks are coming from is visual identified and quantified making for easier repair and greater energy cost savings.

Energy & Emission Reductions

Identify costly compressed air leaks and make large energy & emission reductions. Other benefits include reduced plant noise, increased air compressor capacity and reduced compressor maintenance.

Pinpoint Leaks

With acoustic imaging, the exact area where compressible gas leaks are coming from is visual identified and quantified making for easier repair and greater energy cost savings.

Custom Reporting

Custom easy-to-read reporting that gives a full summary of leakage rates, associated energy and emission saving potentials and clear imagery showing the leak location and area of leak.

Refrigerants & Gases

Acoustic imaging can be used for the detection of refrigerant leaks and other expensive compressible gases such as CO2, LPG and natural gas.

Acoustic Imaging

Refrigerants & Gases

Acoustic imaging can be used for the detection of refrigerant leaks and other expensive compressible gases such as CO2, LPG and natural gas. Topping up refrigerant gases is not only an unnecessary expense but the release of these gases can have a massive environmental impact due to their high Global Warming Potential (GWP).

Stopping refrigerant leaks not only benefits the environment but also helps save money and enhances the longevity and reliability of your refrigeration equipment, saving on maintenance and replacement costs in the long run.

Refrigeration Systems

Topping up refrigerant gases is not only an unnecessary expense but the release of these gases can have a massive environmental impact due to their high Global Warming Potential (GWP).

Stopping refrigerant leaks not only benefits the environment but also helps save money and enhances the longevity and reliability of your refrigeration equipment, saving on maintenance and replacement costs in the long run.

Carbon Dioxide (CO2)

With the recent 10-fold increase in CO2 costs, small leaks detected through an acoustic imaging survey can amount to tens of thousands of dollars a year in savings. Applicable also to all hospital medical gases.